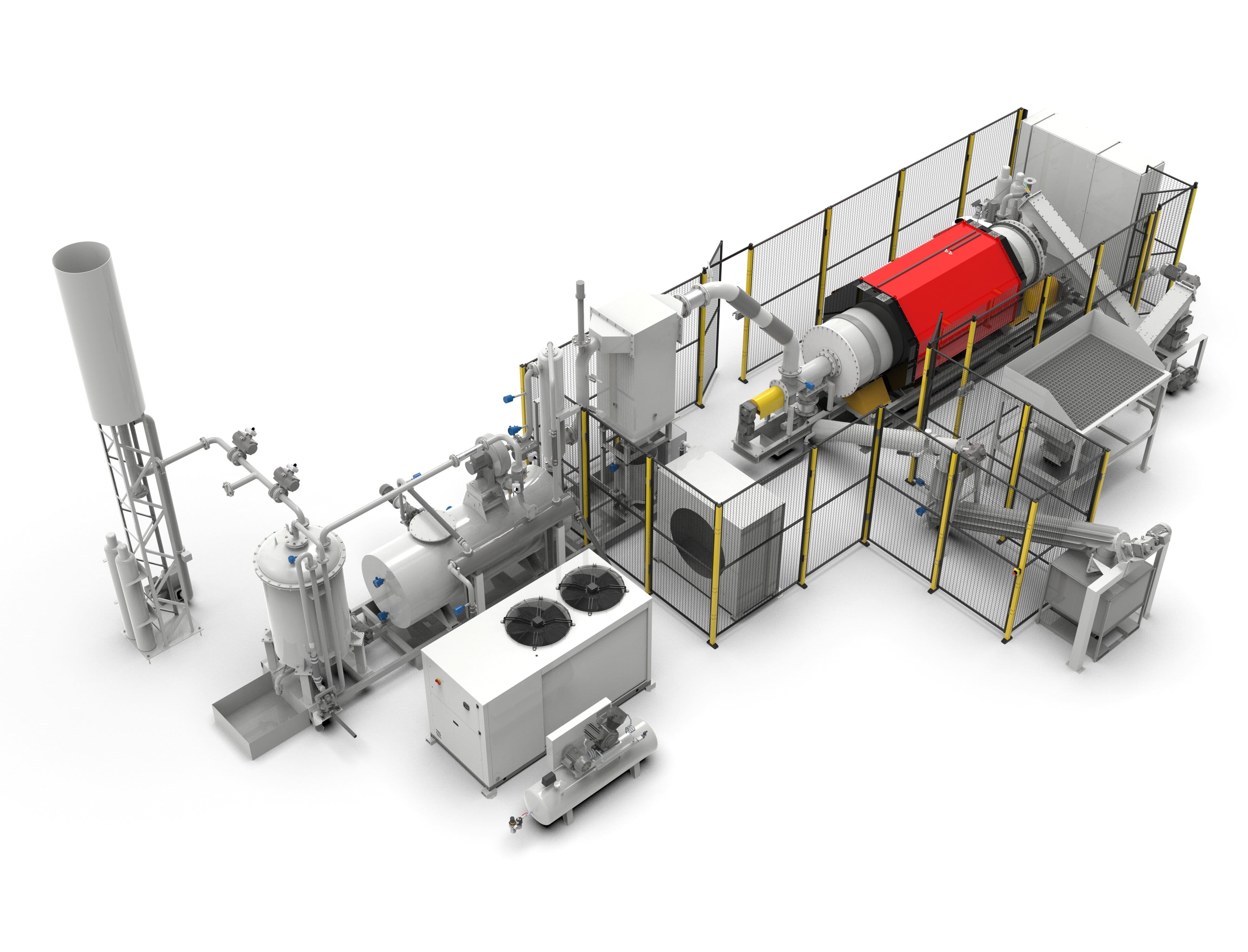

Ervoeco is a unique, innovative catalytic depolymerization technology from LOGeco that is designed to process organic waste (tyres, rubber waste, sewage sludge, plastics, etc.) and convert it into useful raw materials in the form of gas, oil and carbon residue. Depolymerization is a process in which long organic polymers are thermally broken down into simpler molecules, allowing efficient use of organic residues and minimizing waste.

Depolymerization can be thought of as “taking apart a LEGO set”. Imagine that organic waste is like a complex building block, where the pieces are connected into long chains (polymers). These chains are difficult to process in their original state. Depolymerization then causes the individual chain pieces to separate through thermal reactions. This breaks long chains into simpler pieces (molecules), which are much easier to process and more useful for further use.

The principle of this technology is based on the thermal and chemical breakdown of organic substances using lower temperatures, the addition of specific catalysts, all without the presence of oxygen in a hermetically sealed environment. The result is a synthetic gas and oil, both of which can be used as feedstock or fuel, e.g. to generate electricity or thermal energy. In this way, ERVOeco technology breaks down complex organic materials into simpler primary raw materials such as gases, oils and solid carbon residue.

The environmental and circular economy benefits of ERVOeco technology are clear. Processing organic waste through depolymerization reduces the amount of waste and minimizes the negative impacts on the planet.

Composition: The gas component mainly includes nitrogen (N2), hydrogen (H2), methane (CH4) and other hydrocarbons such as ethane (C2H6), propane (C3H8) and butane (C4H10). It may also contain water vapor (H2O) and smaller amounts of other gaseous substances.

Other uses: The produced gas can be used for the production of heat and electricity in cogeneration units. It can also serve as fuel for gas turbines or local energy networks. If the gas is purified and converted to biomethane or hydrogen is separated from it, it can also be used, for example, as fuel for transport.

Composition: The oil fraction contains polyaromatic hydrocarbons, aliphatic hydrocarbons and other organic compounds. The composition and quality of the oil may vary depending on the processed organic waste.

Other uses: The produced oil has a wide range of uses. It can serve as an input raw material for the petrochemical industry, the production of fuels, lubricants and other chemical products. The oil can also be refined and processed to produce biofuels or serve as a renewable raw material for the production of plastics and other polymeric materials. Another possible use is cogeneration and the production of thermal or electrical energy.

Composition: The carbon component is a solid residue after the depolymerization of organic waste. It contains significant amounts of carbon and minerals.

Other uses: This carbonaceous solid component can be used as carbon ash for the production of building materials such as brick or concrete. Thanks to its structure, it can also be used as a fertilizer or used for recultivation and rehabilitation of polluted areas.